- Industrias

- Productos

- Recursos

- Noticias y Eventos

- ¿Cómo comprar?

BÚSQUEDAS SUGERIDAS

Como innovador y fabricante de siliconas, un sólido y talentoso equipo de I+D garantiza que los productos que producimos cumplan o superen las expectativas de nuestros clientes.

Tenemos conocimientos y experiencia significativos en una amplia gama de disciplinas técnicas, incluidas la física de polímeros, la ingeniería de polímeros, la síntesis, la química, la formulación, las ciencias analíticas, las espumas y los materiales celulares. Nuestro equipo técnico incluye Ph.D. científicos e ingenieros junto con expertos en la materia en el desarrollo de aplicaciones de selladores para las industrias electrónica, automotriz, industrial y de construcción.

Nuestro equipo de I+D es vital para nuestro futuro. Estamos desarrollando nuestras competencias básicas mediante la contratación de científicos, ingenieros y técnicos adicionales que fortalecen nuestras capacidades y aportan una mentalidad creativa y pionera al desarrollo de productos. Continuamos aprovechando los avances tecnológicos al invertir en equipos para probar propiedades térmicas, eléctricas y físicas, acelerar el proceso de comercialización y simular los entornos de prueba y fabricación de los clientes.

El espíritu de innovación fluye a través de nuestros laboratorios. Trabajando en conjunto con los gerentes técnicos de ventas, nos enfocamos en el problema o barrera que nuestros clientes están tratando de superar. Estamos muy orgullosos de nuestra tradición de personalizar y desarrollar productos para satisfacer las necesidades específicas de nuestros clientes: hemos introducido más de 60 productos nuevos en el mercado desde 2018.

Con la electrificación de todo, vemos cómo las siliconas podrían desempeñar un papel mucho más importante en el proceso de fabricación. En 2019, comenzamos a diseñar nuestros polímeros de silicona alcoxi patentados y promotores de adhesión y reticuladores avanzados. Estamos avanzando en la próxima generación de productos electrónicos y de alto rendimiento al adaptar siliconas con una amplia gama personalizable de tiempos de curado, propiedades físicas y reologías para adaptarse a la aplicación específica.

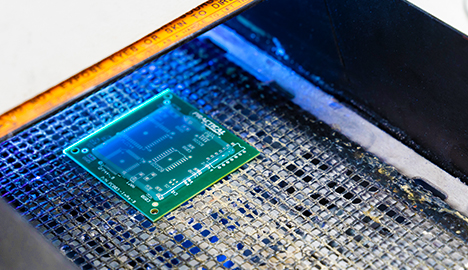

Desarrollamos una tecnología de curado revolucionaria que está transformando el proceso de fabricación de productos electrónicos. Nuestra línea de productos de curado dual/UV sella y protege las aplicaciones electrónicas sensibles con un curado primario UV que se seca en segundos, combinado con un curado alcoxi húmedo secundario que crea adherencia a los sustratos electrónicos comunes mientras elimina el recubrimiento sin reaccionar en las áreas sombreadas. Al combinar la velocidad del curado UV con la seguridad y la integridad de un curado por humedad alcoxi no corrosivo, ofrecemos una capacidad única de curado tanto en las áreas expuestas como en las sombras.

Los materiales de gestión térmica a base de silicona NovaTherm ofrecen una excelente disipación del calor en un amplio rango de temperatura y humedad, lo que los hace especialmente útiles para proteger los componentes electrónicos en condiciones extremas. Junto con la conductividad térmica, brindan adhesión, montaje rápido y protección ambiental.

Podemos adaptar las propiedades físicas curadas y sin curar de nuestras siliconas para necesidades complejas de gestión de interfaces térmicas. El paquete de relleno térmico también se puede modificar para impartir características de rendimiento específicas. Nuestras capacidades de tecnología de polímeros se extienden a los promotores de adhesión, que han cambiado el juego en términos de lo que es posible en el desempeño de la adhesión.

Novagard tiene una larga historia de suministro de adhesivos de sellado de silicona para la industria de ventanas. Las innovaciones recientes se han centrado en reducir el tiempo de producción y lograr un mayor rendimiento. Qwik-Set Glazing Sealant es un producto nuevo e innovador que cura en minutos en lugar de días, lo que permite el movimiento de los ensamblajes minutos después de la aplicación sin que el vidrio se mueva. Qwik-Set ganó un Mercado de puertas y ventanas [DWM] Magazine's 2021 Readers' Choice Award y fue nombrado Producto del año WinDoor 2021/22.

También estamos logrando avances en el mercado de selladores secundarios para vidrio aislante (IG). Estos selladores de vidrio aislante de silicona de fraguado rápido y de un solo componente aceleran la fabricación de unidades de aislamiento térmico. Nuestros selladores IG ahora se encuentran en pruebas extendidas y se espera que se comercialicen en 2023.

Para nuestros clientes de construcción e instalación, ahora ofrecemos una línea completa de productos de construcción de grado profesional. Nuestros selladores adhesivos de silicona se utilizan para ventanas, puertas, revestimientos, canaletas, techos y juntas de expansión. Y fabricamos materiales de instalación y reparación para proyectos de techado comerciales y residenciales.

Además de nuestras siliconas, disponemos de selladores híbridos a base de polímeros. Los híbridos ofrecen algunas ventajas sobre las siliconas, particularmente para aquellas aplicaciones que requieren pintabilidad. Nuestros productos híbridos brindan un excelente equilibrio entre la tasa de curado, la adhesión y las propiedades físicas, y están disponibles en una variedad de viscosidades y características de rendimiento.

Seguimos mejorando y refinando nuestras espumas de PVC Foam Seal. En medio de la pandemia de COVID-19, lanzamos nuestra espuma de grado médico. Esta espuma ha sido probada y certificada de forma independiente para cumplir con el protocolo ISO 10993-10 para contacto directo con la piel. Se utiliza para protectores faciales, máscaras faciales (N95), dispositivos de diagnóstico y accesorios terapéuticos.

También ofrecemos una línea de espumas de alta temperatura que son un reemplazo rentable para EPDM triturado y superan a más

costosas alternativas de EPDM.